Leslie A. Rose Department of Mechanical Engineering

Video

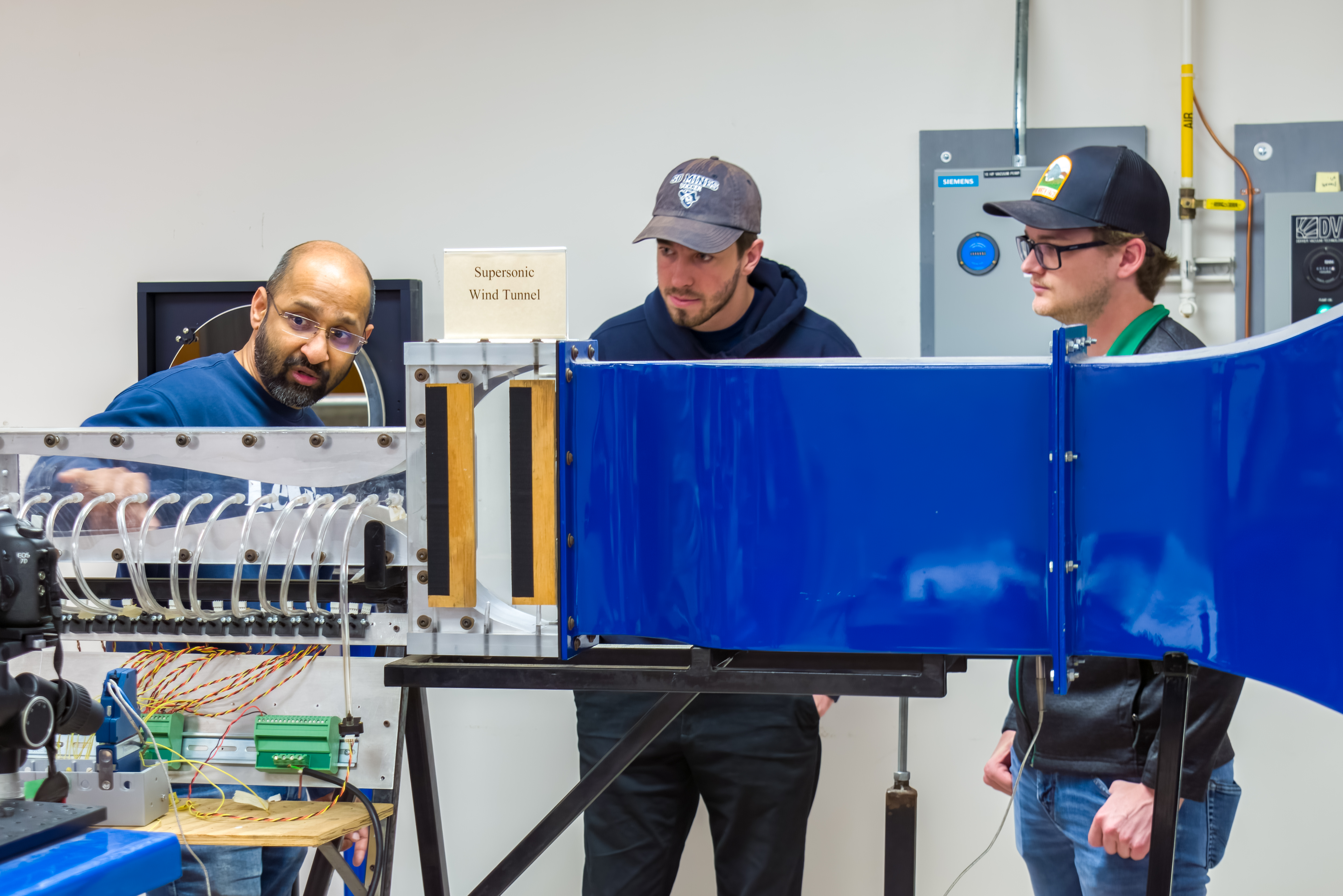

![]() Through hands-on projects and research opportunities, SD Mines ME program has allowed me to push boundaries of what's possible. I am proud to be part of a program that encourages me to dream big and think differently.

Through hands-on projects and research opportunities, SD Mines ME program has allowed me to push boundaries of what's possible. I am proud to be part of a program that encourages me to dream big and think differently.

-

offering a quality education to foster a distinctive curriculum accentuating design and project-based learning;

-

committing to individual development, while emphasizing the values of teamwork in a culturally diverse and multidisciplinary environment; and

-

encouraging undergraduate and graduate research to nurture creative solutions to complex engineering problems.

Department Overview

Les Rose, class of 1970, was born and raised in Meadow, South Dakota, where his parents instilled in him the importance of family, faith, integrity & ethics, honoring your word, and a strong work ethic. These have been his guiding principles throughout his life and his exceptional career. This solid foundation was reinforced through his experience at the School of Mines where his professional journey began.

As the former President of L-3 National Security Solutions (NSS), Les Rose brings decades of experience leading multi-million and billion dollar global organizations. While at NSS, Les oversaw a business segment with over 4,000 employees and $1.2B in annual revenue. NSS delivered best-in-class integrated solutions for complex defense and intelligence customers that span across cyber, intelligence, enterprise/mission IT, command and control, big data, and integrated security. While in this role, he drove efforts to continuously improve and optimize the delivery of new capabilities and proprietary technologies to top customers including government agencies.

Prior to becoming president of L-3 NSS, Les was president of L-3 STRATIS, one of the largest divisions of the global defense leader. Before 2005, he held various leadership roles, all with direct P&L oversight, at Titan Technologies and BTG including president of operational organizations. Through Les’ leadership, facilitating strong customer relationships and contract growth, he grew his organization from a 20 person single program to over 5,000 employees with multiple programs. This business segment supported the rapidly evolving information technology industry in product development, technical services & solutions, earned patents and operated internationally in all continents in the United States as well as Korea, Hawaii, Japan, Middle East, Saudi Arabia, Bahrain, and the UAE. Upon divestiture in 2016, Les started his own business, Titan Technologies, which grew from $20M to $140M over six years, providing meaningful work and professional opportunities to over 800+ employees, including engineers and other technology professionals.

In addition to his extensive leadership, engineering, and technology background, Les is also a Retired Lieutenant Colonel with the United States Army Corps of Engineers where he held high-profile engineering leadership positions with engagements in Europe, the Far East, and Central America until he retired after 20 years of dedicated service.

Les holds a Master of Science in Civil Engineering from the University of Michigan and a Bachelors in Mechanical Engineering from the South Dakota Mines. Les and his family reside in Destin, Florida.

The purpose of the ME external advisory board (EAB) is to advise the Leslie A. Rose Department of Mechanical Engineering of the South Dakota School of Mines & Technology on future direction and development of the department. The foremost role of the EAB is as the “end-user,” providing feedback on the quality of our engineers from an industrial perspective. View the list of current EAB members here.

The South Dakota Mines ME Difference

The South Dakota Mines Leslie A. Rose Department of Mechanical Engineering offers a cohesive, project-based learning curriculum. But unlike many universities, we offer a comprehensive, flexible, and hands-on training program. All students can learn regardless of their level of experience.

Students will choose their focus, pursuing initial training in either manual manufacturing processes or CNC programming processes. Each option has similar limitations, and, therefore, students learn the same theory using the method of their choice. After their required, initial training, students will continue their education in their areas of interest. The project-based learning curriculum is initiated with standard training in ME 126L Design for Manufacturing Lab and refined to student interest with subsequent coursework and projects. Students develop their own projects to maximize interest, ownership, and motivation. This extends to project-based coursework, participation in extracurricular activities, and student-generated, non-academic projects.

The goal of this approach is to help students develop key design for manufacturing skills, which includes process planning, resource planning, material selection, cost analysis, CAD, GD&T, and project management through concurrent engineering and fabrication. We maximize student effort by allowing students the freedom to choose the project. The curriculum teaches industrial culture and safety as priority one. Industrial culture is embedded in the training initiated with the required safety training and lab culture. Lab access is granted after safety training and is maintained through annual refreshers.

Learn more here.

The mechanical engineering program at South Dakota Mines has a project-based curriculum that is focused on product development. A formal product development process has been developed and infused throughout the four years of the curriculum.

Throughout their studies students will be assigned team projects to conceptualize, design, prototype and demonstrate a new product that solves a real-world problem and satiates a social need. What is a product development process? It’s a sequence of steps or activities that are followed in order to conceive, design, and commercialize a product. Our focus is on market-pull product opportunities. Market opportunities are identified and then engineering and science are employed to satisfy that market need. Below is a visualization of where the product development project-based learning takes place in the curriculum and a brief summary of the related activities in each course.

Read more here.

-

ASHRAE (American Society of Heating, Refrigerating, and Air Conditioning Engineers, Inc.)

The American Society of Heating, Refrigerating, and Air-Conditioning Engineers advances the arts and sciences of heating, ventilation, air conditioning, and refrigeration to serve humanity and promote a sustainable world. Membership is open to any person associated with the field, including indoor air quality, building design and operation, and environmental control for food processing and industry. - ASME (American Society of Mechanical Engineers)

ASME helps the global engineering community develop solutions to real world challenges. Founded in 1880, ASME is a professional organization that enables collaboration, knowledge sharing, and skill development across all engineering disciplines, while promoting the vital role of the engineer in society. ASME codes and standards, publications, conferences, continuing education, and professional development programs provide a foundation for advancing technical knowledge and a safer world. ASME helps university students develop their professional identity by offering access to a wide range of activities such as conferences, competitions, scholarships, fellowships, and other programs that will support them through their years in school. - SAE (Society of Automotive Engineers)

SAE has more than 300 collegiate chapters at universities throughout the United States, Canada, and Mexico, and offshore chapters in Bulgaria, Columbia, India, Poland, Spain, and the United Kingdom. Through the guidance of SAE faculty advisors, over 11,000 student members participate in hands-on engineering projects. Many build vehicles to compete in SAE's annual Collegiate Design Competitions, which include Mini Baja, Formula SAE, Aero Design, Supermileage, Walking Machine Decathlon, and Mico-Truck Baja, plus special events featuring alternative fuel vehicles.

South Dakota Mines offers students a unique opportunity to participate in a student-centered, hands-on, engineering program called CAMP.

CAMP is a competitive, nationally recognized program that brings together students, faculty, and industry leaders to partner on real-world projects. Students participating in CAMP can be part of a team preparing for a wide range of national collegiate competitions ranging from robotics to rockets to race cars. CAMP is open to any South Dakota Mines student, any year, any discipline. No prior experience is necessary; just a desire to learn something new.

Through cooperative education (co-ops) and internships, South Dakota Mines students have many opportunities to apply their education to "real world" work experiences. Students are employed by industry and government agencies in positions related to mechanical engineering.

Students may gain 1-3 hours of academic credit for their co-op or internship experience upon department approval. Students registered for co-op courses keep their full-time student status during the semester they are on co-op. All Mines students are encouraged to have relevant work or research experience prior to graduation. Co-ops are often 6-8 months (semester + summer). Internships are usually for the summer or part-time during the school year. However, the terms are used interchangeably by employers.

On average, 75% of South Dakota Mines graduates have relevant work experience upon

graduation.

The average co-op/intern salary for the past academic year was $17.16/hr.

*Some employers also provide housing allowances, bonuses, and relocation expenses

that are not reflected above.

Your co-op experience must be full-time employment and a full semester in length (spring or fall). Summer internships can qualify, but they are limited to a maximum of two (2) credits. An entire explanation of the co-op and internship process can be found here. Students must read through this guide prior to enrolling in any co-op course. Three credits of co-op can be used to satisfy one of your required three credit ME senior electives.

For questions regarding co-op opportunities within the ME department, please contact the co-op advisor, Dr. Joseph John Thalakkottor.

Students for the Exploration and Development of Space (SEDS) empowers young people to participate and make an impact in space exploration. SEDS helps students develop their technical and leadership skills by providing opportunities to manage and participate in national projects as well as to attend conferences, publish their work, and develop their professional network, in order to help students become more effective in their present and future careers in industry, academia, government, and education. Please see the SEDS Student Section at SDSM&T for more details.

- CubeSat

The purpose of this organization is to gather a team of students who are interested in space exploration and nanosatellite technologies. The goal is to work together as a team to design a CubeSat and a specific research experiment for the CubeSat and enter it into the NASA CubeSat Launch Initiative in hopes of getting the CubeSat launched into space. Also with the interest of K-12 outreach and promoting space exploration to the next generation to come. -

High-Altitude Balloon Projects

These projects initiated in the 2016-2017 academic year with the formation of the South Dakota Solar Eclipse Team that prepared a scientific payload to be launched into the path of the 2017 solar eclipse. That team had a successful flight and the project has continued with the development of a cosmic ray detector for future high-altitude balloon flights and potential CubeSat flights. Learn more about the Solar Eclipse Team here. -

MARS (Mines Association of Rocketeers)

MARS is an organization focused on allowing students to engineer, build, and launch rockets. The primary goal of our organization is to get students involved in the aerospace industry and create an interest in rocketry at the South Dakota School of Mines and Technology. -

Moonrockers

The purpose of the Moonrockers team is to coordinate a multidisciplinary effort to design and build a robot that meets the objectives set forth by NASA’s Robotics Mining Competition or related competition. The concepts developed by Moonrockers conceivably could benefit NASA technology and the competition encourages innovative ideas and solutions for the robotics competition. In addition, the team conduct multiple K-12 outreach activities throughout the year. -

NASA Undergraduate Student Instrumentation Projects (USIP)

Two NASA USIP grants were received to support undergraduate projects. The first is associated with multispectral imaging for monitoring crop health. The second is for measuring the helium lift gas in high-altitude balloons. Both projects are being done in collaboration with Raven-Aerostar.

Research Labs & Centers

Work with our renowned faculty and collaborate on groundbreaking projects that address real-world challenges. The hands-on experience and expertise you will acquire here will not only contribute to your academic growth but also prepare you for successful careers in academia, industry, or government agencies.

The overarching goal of the Energy Storage Lab (ESL) is to tackle challenges in the current-generation and to foster innovations for next-generation electrochemical energy storage devices and systems.

The Holistic Engineering Learning Lab & Observatory (HELLO) focuses on design education, design thinking and making, and engineering education research.

Related Topics

Contact Us

For general information:

Phone: (605) 394-2401

Mechanical.Engineering@sdsmt.edu

For information about transfer student advising:

Dr. Cassandra Birrenkott

Professor

Phone: (605) 394-2496

Cassandra.Birrenkott@sdsmt.edu

For information about 1st year student advising:

Mr. Ardell Knudson

Instructor

Phone: (605) 394-5114

Ardell.Knudson@sdsmt.edu

For information about graduate studies:

Dr. Albert Romkes

Associate Professor

Phone: (605) 394-2255

Albert.Romkes@sdsmt.edu