South Dakota Mines Awarded $1.4 Million to Acquire Microscope for Nanoscale Materials Research

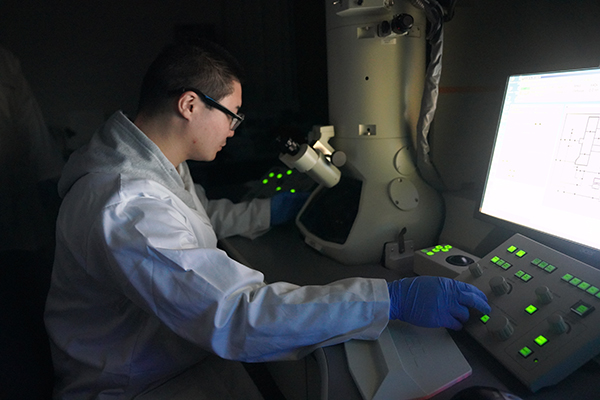

Student and faculty researchers at South Dakota Mines will soon have the capability to explore the tiniest details of materials, even down to an individual atom, thanks to a nearly $1.4 million grant from the National Science Foundation (NSF) to acquire a state-of-the-art field emission scanning transmission electron microscope (FE-STEM).

The equipment, which will support growing research efforts in a wide range of science and engineering fields, is expected to be on campus by the end of the year, said Shan Zhou, Ph.D., assistant professor in the Department of Nanoscience and Biomedical Engineering and principal investigator on the project.

The microscope can view objects as small as fractions of nanometers in size. “This equipment will be beneficial in studying things on a much smaller scale, including the ordering of atoms,” Zhou said. “That is something we can't do with our current equipment on campus.”

Drs. Steve Smith and Congzhou Wang, faculty from nanoscience and biomedical engineering, Grant Crawford from materials and metallurgical engineering and Venkataramana Gadhamshetty from civil and environmental engineering, are co-investigators on the project. The equipment will support a wide range of research, including energy conversion and storage, studying nanoparticles for catalysts and lithium batteries, biomaterials and soft materials, using 2D materials to prevent biofouling, and studying material corrosion and water purification.

“With this new machine, we can look at the atomic structure of the material, the elements

and the composition of the material inside,” Zhou said. “We will also be able to observe

material at cryogenic temperatures or in a liquid environment.”

composition of the material inside,” Zhou said. “We will also be able to observe

material at cryogenic temperatures or in a liquid environment.”

Zhou said that the FE-STEM acquisition will benefit more than 250 people from five research universities and centers in South Dakota and nearby states and open opportunities for industry partners. “We are very confident the addition of this equipment can bring a lot of exciting opportunities not just for academia but for companies who really want to look at the nanoscale structure of their materials,” he said.

Another key feature of the equipment is its automation, which enables potential remote access. "Many smaller schools and companies lack access to advanced research facilities," Zhou said. "The automation capability allows them to easily utilize this high-tech equipment."

This project goes beyond research by using the FE-STEM as a teaching and outreach tool to share the excitement of the nanoworld with the general public. “The microscope can be integrated into existing and new courses with a commitment to teaching and mentoring students of all levels and backgrounds.”

The equipment will be housed in the Engineering and Mining Experiment Station (EMES), a central analytical characterization facility available to the Mines campus and regional academic and industrial partners, along with the current equipment.

“This creates a powerful platform for many different people,” Zhou said. “The resulting infrastructure will provide a fertile collaborative and translational research environment.”