AMP Laboratory

Who We Are?

Who We Are?

We are a multi-disciplinary group of engineers and scientists focused on solving metals material challenges.

Core Technology Areas:

- Cold Spray Technology

- Laser Additive Manufacturing

- Friction Stir Welding/Processing

- Plasma Surface Engineering (PVD, plasma electrolytic oxidation)

Our Mission

Research, Workforce Development and Education, Engineering Service, Outreach

To train and equip the next generation of materials and design engineers in advanced metals processing technologies, and to aid the industry and the nation in developing those technologies for real life applications that will bolster the American manufacturing enterprise.

Research Focus Areas

|

Materials joining Repair technology Additive manufacturing |

Energetic & ballistic material Structure-property-relationships Advanced/functional coatings |

Research

Gas Dynamics of Cold Spray & Control of Deposition (with Video Exhibits)

Ozan C. Ozdemir and Christian A. Widener

January, 2017

Reza Rokni

Ph.D. Dissertation Defense

April, 2015

Recent Journal Articles

- Rokni, M.R., Widener C., and Champagne V.R., “Microstructural Stability of Ultrafine Grained Cold Sprayed 6061 Aluminum Alloy,” Applied Surface Science 290 (2014) 482-489.

- Rokni, M. R., Widener, C. A., Ahrenkiel, S. P., Jasthi, B. K., & Champagne, V. R., “Annealing behaviour of 6061 aluminium deposited by high pressure cold spray. Surface Engineering,” 22 (2014) 63-69.

- Rokni, M. R., Widener, C. A., and Champagne, V. R., “Microstructural Evolution of 6061 Aluminum Gas-Atomized Powder and High-Pressure Cold-Sprayed Deposition,” Journal of Thermal Spray Technology, 2014, 1-11.

Recent Conference Proceedings

- Hammel, Joshua, Langerman, Michael, and Saunders, Nathan, “Radiometric and Metallurgical Analysis of Zone Formation in Elementary Laser Deposited Thin-Wall Structures,” IMECE2013-62142, ASME 2013 International Mechanical Engineering Congress & Exposition, November 15-21, 2013.

- Widener, C.A.; Franklin, J.; Jasthi, B.K.; West, M.K., “Mechanical Properties of Repaired 7075-T73 Friction Stir Butt Welds,” 2013 TMS Annual Meeting, Friction Stir Welding and Processing VIII, March 5-7, 2013.

- Timothy Johnson, Todd Curtis, Bharat Jasthi, Eric East, Christian Widener, Michael West, “Effect of Friction Stir Processing on Armor Grade Materials,” 2013 TMS Annual Meeting, Friction Stir Welding and Processing VIII, March 5-7, 2013.

- Bharat Jasthi, Erik Klinckman, Todd Curtis, Christian Widener, Michael West, Robert Ruokolainen, Ashish Dasgupta, “Effect of Post-weld Aging on the Corrosion Resistance and Mechanical Properties of Friction Stir Welded Aluminum Alloy 7475-T73,” 2013 TMS Annual Meeting, Friction Stir Welding and Processing VIII, March 5-7, 2013.

- Blosmo, D.J., T. Curtis, T. Johnson, N. Procive, C.A. Widener, B. Carlson, R. Szymanski, and M.K. West, FSSW of Mg to Al with a Cold Sprayed Interlayer, TMS Annual Meeting 2011: San Diego, CA. p. 409-416.

- Procive, N., D. Blosmo, T. Johnson, T. Curtis, M. West, and B. Jasthi, C. Widener, Friction Stir Processing of Cold Spray Depositions for Enhanced Surface Properties, in MS&T'11. 2011: CD-ROM, Columbus, OH.

- Widener, C.A.; Blosmo, D.J.; Curtis, T.; Jasthi, B.K., “Investigation of the Repair of Aluminum Cladding Using Supersonic Cold Spray for Corrosion Protection,” 2011 DOD Corrosion Conference, La Quinta, CA, July 31-August 5, 2011.

- Joshua J. Hammell, Christopher J. Ludvigson, Michael A. Langerman and James W. Sears, “Thermal Imaging of Laser Powder Deposition for Process Diagnostics,” ASME 2011 International Mechanical Engineering Congress and Exposition, November 11–17, 2011.

- Sylva, G. and Widener, C.A. “Development of Simultaneous Opposed Welding of Al-7249 Extrusions with Large Recrystallized Grains Using the Self Reacting FSW Process,” 8th International Friction Stir Welding Symposium, Strand, Germany, May 18-20, 2010.

Patents

| Widener, C.A., Hrabe, R.; Champagne, V., “Cold Spray System With Upstream Mixing And Hand Held Spray Nozzle Suitable for Robotic Manipulation,” US Patent Application – 61/719,632, 2012. |

| Widener, C.A.; Hrabe, R.; James, B.; Champagne, V.; Britton, O.; Well, A. ”System for Cold Spray Repair of Aluminum Aircraft Skin Fastener Holes,” US Patent Application - 61/719,641, 2012. |

| Hrabe, R.; James, B.; Widener, C.A.; Champagne, V., “Cold Spray Wear Coating for Hydraulic Lines,” US Patent Application, 61/719,636, 2012. |

Articles Online

AMP Lab News

SD US Senator Press Release - 9/15/21

Grant Awarded to South Dakota School of Mines and Technology for DoD Cold Weather

Research

Forbes - 7/28/21

Cold Spray Technology Could Allow Air Force To Quickly Repair Aircraft Parts Instead Of Replacing

Them

Rapid City Journal - 2/23/14

Future being created at Rapid City business incubator

Argus Leader - 2/8/14

S.D. university scientists unite to reveal words behind the masks

Prairie Business - 10/25/13

ECONOMIC DEVELOPMENT:Public/private partnerships promote positive economic development

Ellsworth AFB News - 3/27/13

Cold spray could bring AF 10-1 investment return

Cold Spray News Links

Business Wire - 11/7/13

GE Researchers Experiment with 3D Painting to Build Up and Repair Parts

SERDP / ESTCP News – Fall 2013

Cold Spray Technology for Aircraft Component Repair

Fox News - 1/3/13

Can a cold, green, supersonic spray save the Black Hawk?

Capabilities

Core Technologies

Focused on advanced metals deposition technologies, we’ve strived to be nationally and internationally recognized for our contributions to these areas.

Friction Stir Welding

What is Friction Stir Welding

Friction stir welding is a completely solid-state welding process that relies on local forging and extrusion created by a rotating pin tool.

Advantages of Friction Stir Welding

-

No melting of materials

-

Low heat input into substrate –> Minimal degradation and/or distortion

-

Very high joint strengths possible -> Typically 70-90% joint efficiency

-

Full penetration joints in a single pass -> Thicknesses from 0.020 in. to 3 in.

-

Highly dissimilar materials can be joined

-

Virtually all metals and many plastics can be joined

Laser Powder Deposition

Cold Spray

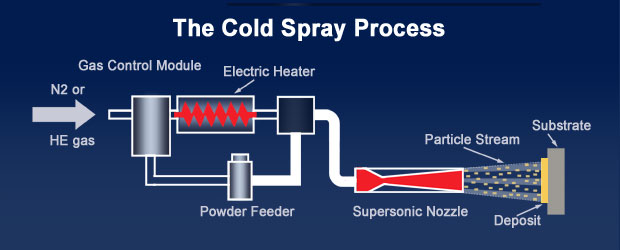

Cold spray is a lower temperature solid-state thermal spray process that deposits metal powder using a heated inert gas through a supersonic nozzle.

Advantages of Cold Spray

- No melting of powder materials

- Low heat input into substrate –> Minimal degradation and/or distortion

- Very high adhesion strengths possible -> Greater than 10 ksi

- No limit on thickness -> Deposits can be from 0.001 in. to 1 in., or even more

- Highly dissimilar materials can be combined

- Virtually any metal can be deposited

- Deposition possible on both metallic and non-metallic surfaces

Plasma Surface Engineering

Plasma Vapor Deposition & Plasma Electrolytic Oxidation

Physical Vapor Deposition (PVD)

Solid target (metals, alloys, ceramics) vaporized by plasma, condensed on substrate (metals, ceramics, polymers, composites) to form thin films and coatings.

Applications: wear resistance, solid lubrication, optical & electronic layers

Plasma Electrolytic Oxidation (PEO)

High voltage electrochemical process where plasma discharges convert metal (Al, Ti, Mg, Zr) surfaces into hard, ceramic layers

Applications: wear resistance, corrosion resistance, thermal protection, biocompatibility.

Core Research Foci

Advanced Manufacturing

Our newest capability brings 6-axis direct CAD-to-Motion path planning and tool changing capability for integrating multiple processes on a single platform.

3-D Printing

Using both direct write and laser processing technologies, we are looking at how the future of manufacturing is changing by creating complex parts directly from computer models.

Repair

Helping industry and the Department of Defense find ways to save millions of dollars and the environment by repairing and remanufacturing parts instead of replacing them with new ones.

Other Capabilities

- Materials Characterization & Testing

- Prototyping

- Reverse Engineering

- Technology

AMP Lab Equipment

The lab is home to a range of state-of-the-art metals deposition and joining technologies, and is well instrumented for data capture of critical process parameters for both research and development and statistical process control evaluations for qualification.

Major Equipment

ISTIR 10 Friction Stir Welding 5-axis System

5-axis Motion with add'l forge and pin actuation for self-reacting and retractable pin tool welding. 7-axis force monitoring. Working envelope: 39” x 120” x 48” (X,Y,Z); Tool Rotation: 200-2000 rpm; Max. Forge Force: 20,000 lbs

MTS/Optomec 3kW Laser Powder Deposition Sys.

This is a custom LENS based system using a TRUMPF 3kW Nd-YAG laser, and options for 3-6 axis, in or out of chamber, and 3-D printing or cladding, and internal bores to 2 in.

VRC Gen III Cold Spray High Pressure System

With the option for hand-held operation, and the capability to reach 1000 psi and 900 C, this system can do a lot.

Riftec/HFW Refill Friction Stir Spot Welder

Refill Spot Welding system with 1-axis weld head. Produces flush, fatigue resistant friction stir spot welds. Material thicknesses up to 3/16” thick.

Kurt J. Lesker Company PRO Line PVD 200 Thin Film Deposition System

VDK 6000 Laser Deposition System

Advanced 6-axis motion system with CAD-to-Motion control using a Flexible Robotic Environment™ and a tool holder for both additive and subtractive, as well as inspection tools.

Lab Safety

Lab Safety

The manuals, best practices and safety procedures available below are to be followed in order to insure safe practices in the AMP Laboratory.

South Dakota Mines Emergency Procedures Webpage

Other Equipment

|

Supporting Equipment

|

Other Equipment Available at South Dakota MinesExperimental Mining & Experiment Station

|

Have more questions?

Mailing address:

Attn: Grant A. Crawford – AMP

South Dakota School of Mines & Technology

501 E. Saint Joseph St.

Rapid City, SD 57701